The Advance of Automatic Computerized Wire Stripping Machines

Publication time:2024/11/13 14:34:12

Source:

Shenzhen Qirui automation equipment Co., LTD

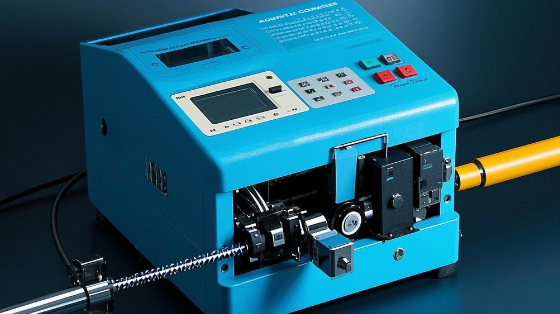

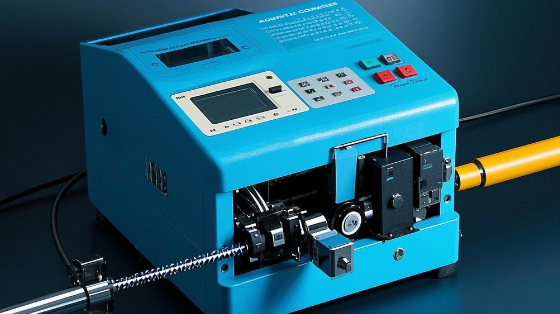

In the dynamic world of high-tech manufacturing, the automatic computerized wire stripping machine has emerged as a vital tool, revolutionizing the way wires are prepared for various applications. This advanced piece of equipment combines precision engineering with cutting-edge computer control technology to offer manufacturers a highly efficient and accurate solution for wire stripping.

The wire stripping process in these machines is based on advanced algorithms and sensor technology. The machine is equipped with high-precision cutting blades that are carefully calibrated to remove the insulation from the wire with utmost accuracy. The computer control system allows for precise adjustment of the stripping parameters, such as the length and depth of the strip, depending on the specific requirements of the wire and the application. This level of precision is essential in industries where the integrity of the wire is critical, such as in the production of high-quality electronics, automotive wiring harnesses, and aerospace components. For example, in the aerospace industry, even a slight deviation in the wire stripping process could lead to electrical interference or signal loss, which could have serious consequences for the performance and safety of the aircraft.

One of the key advantages of the automatic computerized wire stripping machine is its ability to handle a wide variety of wire gauges and insulation types. The machine's software can be programmed to recognize different wire characteristics and adjust the stripping process accordingly. This flexibility is crucial in modern manufacturing, where a single production line may need to process multiple types of wires for different products. Whether it's a thin wire used in a miniature electronic device or a thick cable for industrial machinery, the automatic computerized wire stripping machine can handle the task with ease and precision.

The control system of the machine also offers significant benefits in terms of productivity and quality control. It allows for batch processing, where multiple wires can be stripped in a single operation, reducing the overall production time. The system can also monitor the stripping process in real-time, detecting any errors or abnormalities and alerting the operator immediately. This helps to ensure that each wire is stripped correctly, minimizing the production of defective parts. For instance, if the machine detects an incorrect wire gauge or a problem with the cutting blade, it can stop the operation